Trenchless rehabilitation solution for ageing pressurised pipelines.

Wavin Compact Pipe® is designed for use in existing pressure and gravity pipelines for the renewal of drinking water, gas, and wastewater pipelines made of steel, cast iron, or concrete.

It is installed close-fit into an existing pipeline providing a new structural pipe with a lifetime of 80 – 100 years’ service.

The tight-fitting Compact Pipe acts as a fully independent pressure pipe, ensuring structural integrity even in damaged or cracked host pipes.

Once installation is completed the Compact Pipe will have the same qualities as standard PE pipes.

Features

Uses PE 100, a high-grade polyethylene with excellent mechanical and chemical resistance properties.

Highly abrasion resistant so is ideal for rising mains.

Installation in continuous lengths range from 93 m [DN 500] up to 600 m [DN 150] from a single coil.

Can cope with all bends up to 22.5 degrees

Suitable for various pipeline materials (steel, cast iron, concrete)

Can handle high-pressure applications up to 16 bar (water) and 10 bar (gas)

Benefits

• Best value – Double the life and half the cost it is the cheapest solution on the market

• Longer lasting – Exceptional strength and longevity, outperforming many other rehabilitation methods

• Ease of install – Trenchless technology means minimal surface disruption and shorter installation times

• Maintainable – It can be connected to, repaired and cut into again, and it is repairable and maintainable by in house team

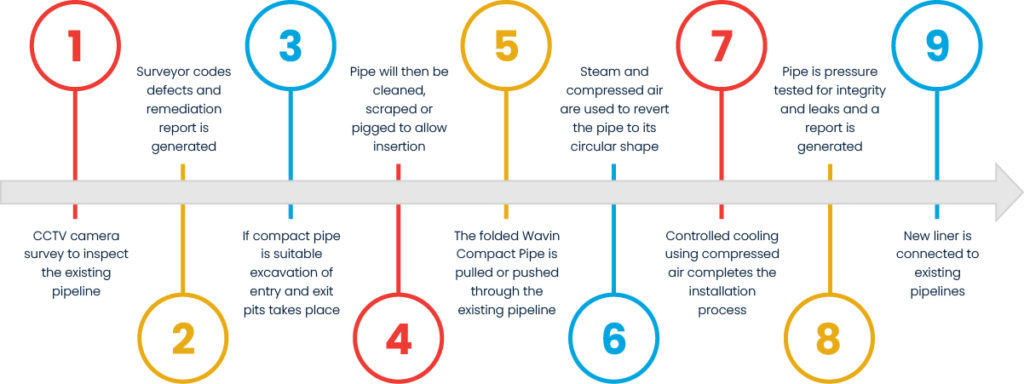

Installation process

PSS can provide an end-to-end solution from initial survey, cleaning and preparing the host pipe to installation and pressure testing before handing back to be connected to existing pipelines.

The process

1. CCTV camera survey to inspect the existing pipeline

2. Surveyor codes defects and remediation report is generated

3. If Compact Pipe is suitable excavation of entry and exit pits takes place

4. Pipe will then be cleaned, scraped or pigged to allow insertion

5. The folded Wavin Compact Pipe is pulled or pushed through the existing pipeline

6. Steam and compressed air are used to revert the pipe to its circular shape

7. Controlled cooling using compressed air completes the installation process

8. Pipe is pressure tested for integrity and leaks and a report is generated

9. New liner is connected to existing pipelines